Screenprint vs linocut vs etching: choosing the technique your brief needs

Need a tactile print that nails brand storytelling? This guide compares screenprint, linocut and etching head-to-head so you can match project goals to the perfect technique—without wasting time or budget.

Why technique choice matters for today's briefs

Print buyers juggle deadlines, sustainability demands and distinctive visual impact. Selecting screenprint vs linocut vs etching early clarifies:

- Turnaround speed and cost per unit

- Edition size and collectability

- Paper, ink and plate requirements

- Environmental footprint and brand values

Making that call late can double production time or force rushed compromises. Let's dive into the specifics.

Technique snapshots

Screenprint: colour layering power

Screenprinting pushes ink through a mesh stencil. Each colour needs a separate screen, making bold, flat tones pop.

- Ideal for: posters, apparel, limited-edition merch.

- Max sheet size: up to A0 with professional carousels.

- Texture: slight raised ink gives a premium feel.

- Sustainability call-outs: water-based inks and reusable aluminium frames cut waste—see these eco-friendly ink guidelines.

Linocut: the artisan's stamp

Linocut involves carving a design into linoleum, inking the block and pressing it onto paper.

- Ideal for: expressive illustrations, zines, art cards.

- Edition size: 20–50 before detail degrades.

- Setup cost: low—one carving tool kit and a press.

- Texture: visible chisel marks add authenticity.

Etching: detail for days

Etching uses acid to bite lines into a metal plate, capturing hairline details impossible with knives.

- Ideal for: fine-art editions, architectural plans, luxury stationery.

- Edition size: 50–100 before plate softens.

- Setup cost: highest—metal, grounds, acid baths, safety gear.

- Texture: deep plate impression and velvety ink tone.

Cost, speed and edition comparison

| Factor | Screenprint | Linocut | Etching |

|---|---|---|---|

| Average setup cost (EUR) | 150 | 30 | 200 |

| Typical turnaround (days) | 5 | 3 | 7 |

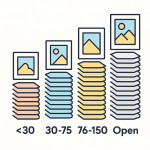

| Comfortable edition size | 100–300 | 20–50 | 50–100 |

| Ink layer thickness | Medium-High | Low | Medium |

| Best for colour gradients | Yes | Limited | No |

Source : Printmakers Guild

Decision flow: match brief to process

- Define detail vs impact. Need crisp linework under a loupe? Etch it. Want eye-catching broad shapes? Screenprint wins.

- Confirm palette size. Four colours or fewer keep screen costs sensible. Single-colour illustration? Linocut cuts hours off prep.

- Check edition ambitions. Anything above 100 prints favours screenprint; collector-grade runs under 50 lean to linocut.

- Assess budget ceiling. If setup must stay under €50, linocut is the only option.

- Map timeline. Campaign launch in four days? Screenprint or linocut; etching's acid baths demand patience.

Licensing and resale considerations

Collectors track edition numbers closely. Brush up on numbering conventions through our guide on edition numbering rules. For brand campaigns, screenprint's scalable editions lower unit price for giveaways yet still feel exclusive.

Eco impact and brand storytelling

With CSR audits growing, material choices matter as much as aesthetics. Linocut's water-based relief inks score well on VOC emissions. Screenprint's solvent inks can be swapped for certified plant-based alternatives—see our sustainable inks checklist. Etching traditionally uses harsh acids, but citric and salted etch solutions now reduce hazards.

Collaborating with a professional printmaker

Even seasoned art directors rely on specialist knowledge. A vetted print studio helps fine-tune paper weight, ink mix and plate prep. Not sure where to start? Our piece on hiring a printmaker in 2025 outlines briefing templates and fair day rates.

Already planning a product-launch drop? Sync proofs, teasers and e-commerce stock levels with the print-drop roadmap.

For complex image composites, many art directors consult specialised image designers who translate high-resolution files into plate-ready separations that rival in-house pre-press teams.

QUIZ: test your technique IQ

FAQ

- Can I combine techniques in one project?

- Yes. Many studios print a linocut key image, then screenprint gradient backgrounds for vibrancy.

- Which process is safest for children's art workshops?

- Linocut with water-based inks—no chemicals, minimal sharp tools when using soft-cut blocks.

- How do I store metal plates after etching?

- Clean thoroughly, dry, then apply a microcrystalline wax to prevent oxidation.

- Does screen size limit detail?

- High-T mesh counts (140T+) retain fine 0.15 mm lines, but etching still wins for micro-detail.

Wrap-up & next steps

Matching screenprint vs linocut vs etching to your creative brief saves money, honours deadlines and amplifies brand story. Ready to lock in a process? Reach out to a vetted printmaker today and turn that concept into a tangible, collectable statement piece.

CTA: Need a production quote within 24 h? Contact our studio network and secure your print slot before schedules fill.