Creating digital twins for stage sets: scan-to-build loops that slash revisions

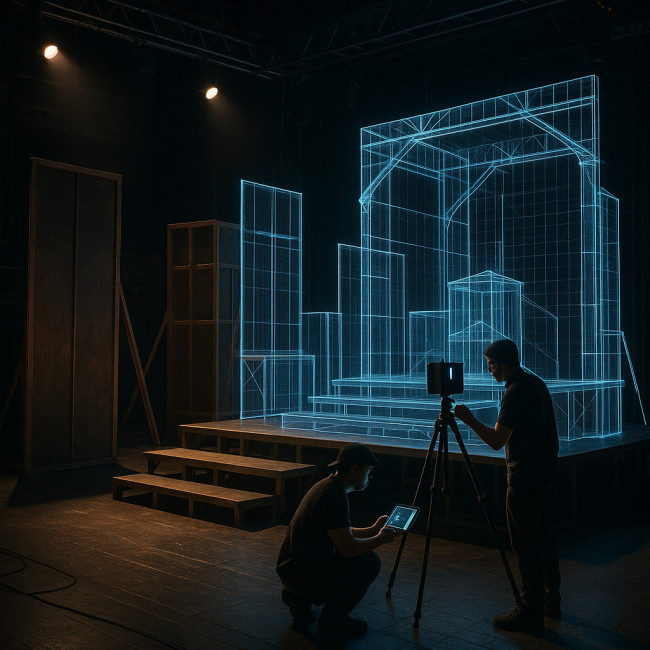

Tired of late-night set revisions and surprise clashes during tech week? Digital twins built from fast 3D scans let production teams rehearse changes virtually, fix issues early and send fabrication-ready files to workshops. Follow this guide to create a scan-to-build loop that shrinks your revision cycles by 50 % or more.

Why digital twins transform stage production

Traditional stage design still relies on a mix of 2D drawings, foam models and endless PDF mark-ups. Every disconnect between concept and construction adds costly rework. A digital twin—a live 3D replica of the set—aligns directors, scenographers and carpenters in one shared space. Updates ripple instantly across lighting plans, safety checks and budget forecasts, so you spend more time perfecting the show, not patching mistakes.

- Fewer onsite surprises: run virtual walk-throughs before a single beam is cut.

- Lean budgets: early clash detection saves lumber, paint and crew overtime.

- Faster approvals: producers review changes in minutes instead of overnight renders.

- Accessible archives: keep the twin as a template for touring or sequels.

The scan-to-build loop in five actionable steps

1. Rapid LiDAR or photogrammetry capture

After a blocking rehearsal, scan the bare stage with a LiDAR-enabled tablet or a DSLR photo rig. Aim for a point-cloud density of 5–10 mm to balance file weight and structural accuracy. Label tripod positions for repeat scans when the set evolves.

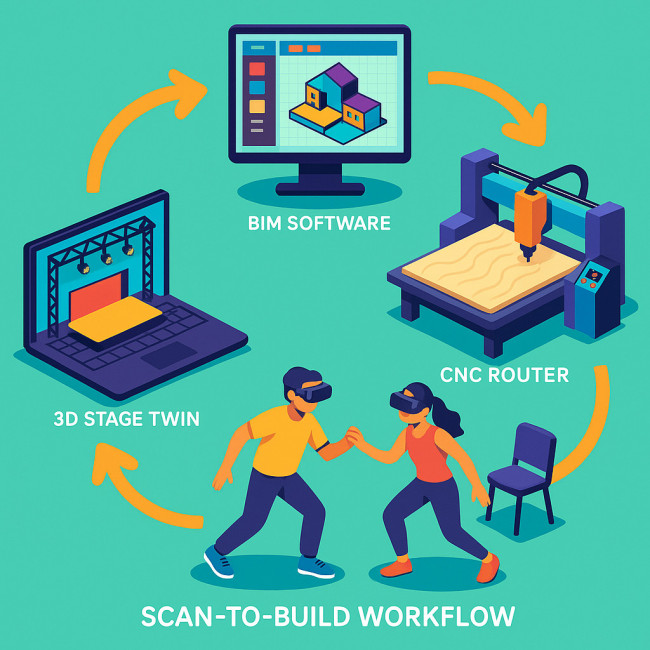

2. Cloud-to-BIM conversion

Import the point cloud into software such as Revit, Vectorworks or BlenderBIM. Auto-classify planes into walls, floors and risers, then assign material attributes. This creates a parametric model that lighting, rigging and sound teams can query in real time.

3. Virtual rehearsal and change logging

Sync the BIM model with a real-time engine (Unreal or Unity). Directors can test sightlines, while choreographers validate pathway widths. Every note is stored as an issue ticket, giving a single source of truth for craftspeople.

4. Automated fabrication drawings

When a note is approved, generate cut lists directly from the model. Connected CNC routers or laser cutters receive updated DXF files, eliminating manual redraws. This mirrors the best-practice documentation packs that top workshops expect.

5. Continuous validation scans

After each build sprint, perform a quick rescan. Overlay the new cloud on the BIM file to spot deviations greater than 3 mm. Fixes happen the same day instead of during final technical runs.

Recommended tech stack

| Process | Tool Type | Affordable Option | Pro Option |

|---|---|---|---|

| Scanning | LiDAR tablet | iPad Pro + Polycam | Leica BLK360 |

| Point-cloud clean-up | Desktop software | CloudCompare | Autodesk ReCap Pro |

| BIM modeling | CAD/BIM | BlenderBIM (open-source) | Revit + Dynamo |

| Real-time review | Game engine | Unreal Engine (free tier) | Unity Industry |

| Fab integration | CNC router | ShopBot Desktop | AXYZ Infinite Series |

Need to layer augmented effects onto the twin? Check out our guide on bridging AR and stage crews.

Implementation roadmap for theatres and festivals

- Kick-off audit: Map existing design workflows and pinpoint revision pain points.

- Pilot a single set piece: Start with a modular platform or pivot wall to prove ROI in one production cycle.

- Upskill your team: Run short workshops on LiDAR capture and BIM editing. Many specialised spatial design studios offer remote coaching packages.

- Integrate budgets early: Use cost data to justify hardware purchases. Our article on scenography budget tiers details persuasive metrics.

- Scale across productions: Once the loop runs smoothly, template your settings so visiting designers can plug in without friction.

Real-world impact: two quick wins

Win #1 — 30 % faster approvals. A touring musical in Lyon cut the director's note turnaround from 72 to 48 hours by sharing an interactive twin instead of static PDFs.

Win #2 — 20 % material savings. A university theatre avoided re-cutting curved flats after overlay scans exposed mis-aligned ribs before plywood was glued.

Common challenges and fixes

- File bloat: Compress point clouds and purge hidden geometry. Limit texture maps to 4K.

- Hardware learning curve: Pair novices with a scanning mentor during the first two calls.

- Workshop pushback: Demonstrate how cleaner DXF files reduce overtime, turning resistance into enthusiasm.

- Data silos: Host the twin on a shared cloud drive with role-based permissions so departments tug from the same source.

FAQ

- Do I need high-end scanners to start?

- No. Modern LiDAR-enabled tablets capture enough detail for 90 % of sets under 12 m wide.

- How often should I rescan the build?

- After every major scenic install or when notes alter structural elements.

- Will the process slow my art department?

- Expect a short learning curve. Most teams report time savings from week 2 onward.

- Can freelancers access the twin remotely?

- Yes. Host the model on cloud BIM platforms with granular permission settings.

- Is the investment justified for small venues?

- Even a 50-seat black-box saved €1 500 in plywood on its first digital-twin show.

Quick self-assessment

Conclusion & next steps

Digital twins move stage design from guesswork to data-driven precision. Start scanning a single set piece, refine your workflow, and soon your team will iterate faster than ever. Ready to dive deeper? Explore how collaborative lighting sync tools plug straight into your twin. If you need expert support, reach out—our community is eager to help you put the curtain up on time and on budget.

CTA: Want a personalised roadmap? Book a 30-minute discovery call and get your first scan-to-build template free.