From one-off to small-batch: production pathways for scaling object design orders

You have mastered the art of crafting unique objects. Now clients are asking for ten, fifty, or even two hundred units. This guide shows you how to move from single prototypes to reliable small-batch production without losing design integrity, cash flow, or sleep.

Why move beyond one-off pieces?

Producing a lone prototype trains your creative muscles, but it rarely funds long-term growth. Small-batch production can:

- Multiply revenue by amortising design time over several units.

- Validate market demand before committing to mass manufacture.

- Attract retailers who need consistent inventory, not one-offs.

- Improve sustainability because shared tooling and bulk material purchases reduce overall waste.

Mapping production pathways

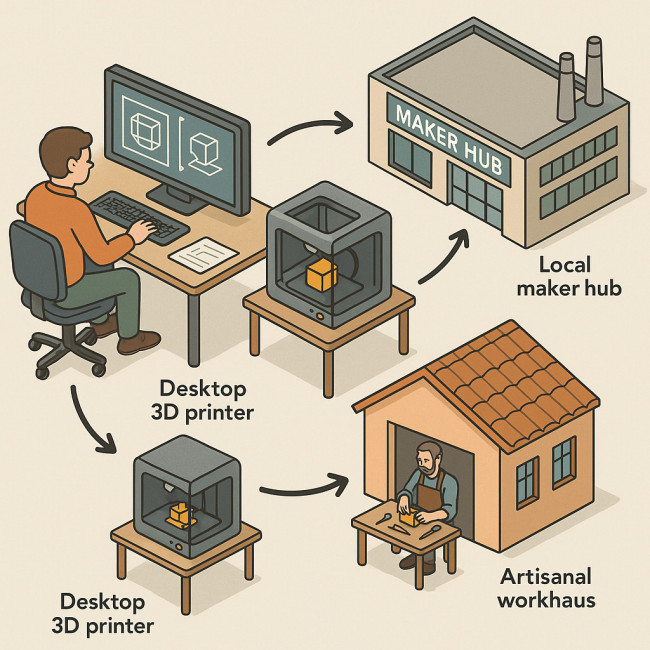

This visual walkthrough captures the entire journey at a glance: a designer renders a CAD model on a laptop, hands it off to a desktop 3D printer for the first proof, then tests batch-ready jigs on a laser cutter, while shipping icons trace how files travel to local maker hubs, artisanal studios and finally specialised factories. Seeing every pathway on one canvas helps readers memorise which option matches order size, budget and lead-time, so refer to the illustration as you read the five routes below.

1. In-house micro-runs

You continue producing in your own studio but add simple jigs, batch-friendly moulds, or a desktop CNC. Volumes usually top out at 20–50 units per month.

2. Local maker hubs

Makerspaces and fab-labs give you pay-per-use access to laser cutters, industrial 3D printers, or small kilns. They shine for 50–150 units when your equipment budget is tight but you still want on-site oversight.

3. Distributed digital fabrication networks

Platforms such as Craftcloud or MakeXYZ farm your CAD file out to vetted workshops close to your end customer. Lead times drop because shipping happens regionally, and you skip import duties on sub-200-unit runs.

4. Regional artisanal workshops

Think family-run foundries, glass studios, or woodshops capable of 100–500 identical pieces. You gain traditional craftsmanship plus the flexibility to refine finishes between batches—ideal for limited editions that may later feed royalty-based collections.

5. Specialised small factories

Facilities dedicated to “low volume, high mix” manufacturing use semi-automated lines that scale from 500 to 2 000 units. They expect professional documentation, so review the object designer–engineer workflow checklist before your first call.

Cost, lead time and MOQ comparison

| Pathway | Typical MOQ | Cost per unit* | Average lead time |

|---|---|---|---|

| In-house micro-run | 1–50 | €35–€120 | 1–3 weeks |

| Local maker hub | 20–150 | €18–€90 | 2–4 weeks |

| Distributed fab network | 30–300 | €15–€70 | 7–21 days |

| Artisanal workshop | 50–500 | €22–€85 | 3–6 weeks |

| Small specialised factory | 250–2 000 | €8–€40 | 4–8 weeks |

*Costs vary by material, finish, and regional labour rates. Use them as directional anchors when budgeting.

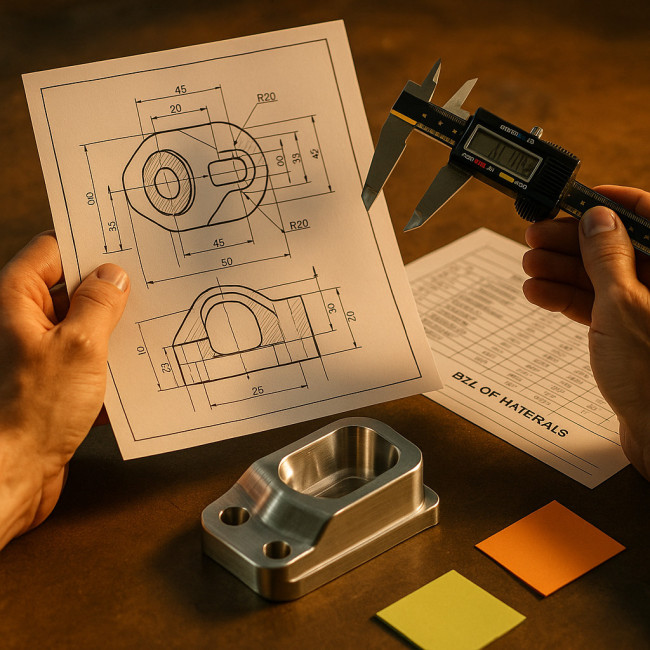

Preparing your design for scale

Look closely at the drawing-and-prototype duo in the picture: every dimension is double-checked with digital calipers, red ink circles highlight tolerance hotspots, and a colour-coded bill of materials sits within arm's reach. Even the handwritten tape flags surface roughness that must stay under 0.8 µm. This degree of clarity does more than impress engineers—it eliminates costly back-and-forth, shrinks sample iterations, and keeps your cash flow free for marketing instead of retooling. Use the scene as a mental checklist before hitting “send”.

Before you email a factory, ensure your prototype is truly production-ready. A clear technical package reduces sampling rounds and protects margins.

- Lock dimensions and tolerances. A prototype timeline benchmark keeps every stakeholder aligned on revisions.

- Simplify assemblies. Fewer parts equal fewer defects.

- Choose scalable materials. Refer to sustainable material sourcing strategies to prevent supply bottlenecks at higher volumes.

- Create jig-ready geometries. Rounded edges, uniform wall thickness, and draft angles turn artisanal love into repeatable quality.

- Document finishing steps. Photographic guidelines help external teams colour-match accurately, especially when they consult the craft-designer directory profile you maintain for reference.

How to choose the right pathway

Decision factors vary by project, but the matrix below simplifies the trade-offs:

- Order size forecast: Under 100 units? Stick to in-house or local hubs. Beyond 250? Gather quotations from factories.

- Cash-flow tolerance: Up-front tooling fees may hit €2 000–€8 000 in factories; hubs rarely exceed €400.

- Brand story: If hand-crafted heritage is core, artisanal workshops justify higher per-unit costs.

- Speed to shelf: Digital fabrication wins when you must deliver within a month.

- After-sale support: Factories often bundle packaging and drop-shipping, freeing your studio for new R&D.

Quick self-diagnosis quiz

FAQ

- How small is “small-batch” in the object-design world?

- Most studios define small-batch as 50 – 2 000 identical units—big enough to need repeatability, small enough to avoid big-box retail commitments.

- What documentation do factories expect?

- A 3D file (STEP or IGES), 2D drawings with tolerances, a bill of materials, and finishing instructions. Quality photos of your approved prototype are also welcome.

- Can I keep my artisan narrative if I outsource?

- Yes. Many designers mention workshop heritage or limited-edition numbering on packaging to maintain authenticity even when runs are produced externally.

- How do I protect my intellectual property?

- Use NDAs, register design patents where possible, and split tasks between suppliers so no single partner owns the full process.

- Is overseas production always cheaper?

- Not necessarily. Shipping, duties, and communication delays can offset lower labour costs on orders under 1 000 units.

Next steps

Choose one upcoming design and run it through the cost-lead-time matrix above. If figures align, request quotes from two pathways this week. For deeper guidance, explore questions to ask small-batch makers and bookmark this guide for your team.

Ready to scale smart? Subscribe to our monthly digest and receive templates that cut your quotation time in half.