Recycled glass sourcing playbook: greener materials that impress eco-clients

Want to shrink carbon footprints, dazzle eco-minded buyers, and still keep production costs in check? This playbook walks you through every stage of sourcing recycled glass—from defining technical specs to proving traceability—so that your next object, lighting, or architectural project earns instant green credibility.

Why recycled glass is stealing the spotlight

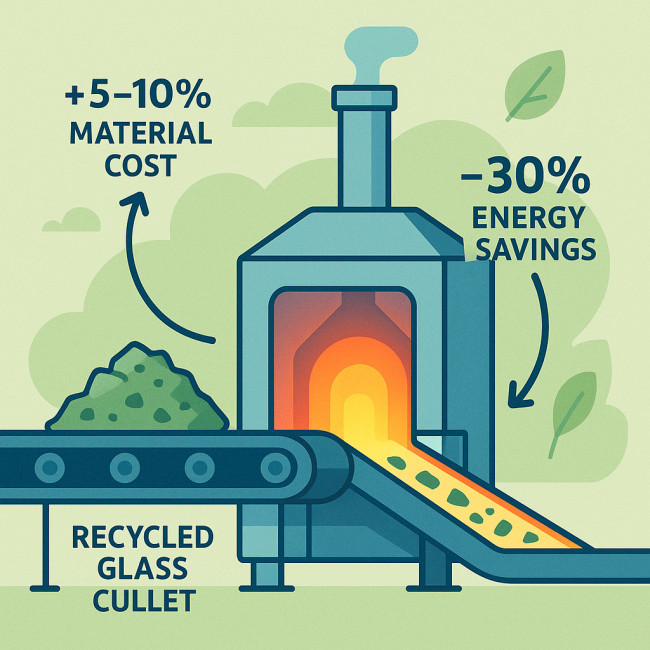

Using recycled glass cullet instead of virgin silica cuts energy consumption by up to 30 %, lowers raw-material costs, and diverts tons of waste from landfills. Forward-thinking brands know it, and savvy makers who master cullet procurement routinely win briefs over competitors still relying on new glass.

- Energy savings translate to lower firing bills and faster furnace cycles.

- Marketing appeal: eco-certifications elevate your profile on any sustainable design brief.

- Greater storytelling power: recycled origins resonate with audiences browsing the craft-designer directory for planet-friendly talent.

Source : European Environment Agency

The 5-step recycled glass sourcing workflow

1. Define project-ready specifications

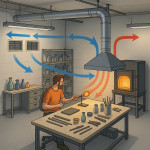

Start by listing thermal expansion requirements, colour tolerance, and acceptable bubble count. Clear specs help suppliers slot you into the right cullet stream and prevent costly re-melts.

- Match coefficient of expansion (COE) to existing batch formulas.

- Set maximum allowed heavy-metal ppm to align with RoHS and food-contact rules.

- Note colour shift limits (ΔE* < 2) if you'll incorporate pigments later.

2. Map regional cullet streams

Transport emissions can wipe out green gains. Geo-filter cullet yards within a 300 km radius and compare grades. When pitching to brands focused on localism, this data pairs nicely with geo-targeted storytelling.

3. Vet suppliers for transparency

| Supplier | Cullet purity | Traceability docs | MOQ | Lead time |

|---|---|---|---|---|

| GlassCycle EU | 99 % | EUREC certificate | 1 t | 10 days |

| GreenShard US | 96 % | UL ECVP 2799 | 500 kg | 14 days |

| CulletWorks Asia | 97 % | ISO 14021 | 2 t | 21 days |

Ask for batch test reports and independent audits. Suppliers who refuse usually fail client compliance screens.

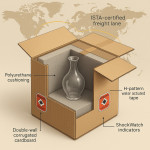

4. Secure chain-of-custody evidence

Eco-clients, especially corporate architects, often demand cradle-to-gate tracking. Combine supplier declarations with your own kiln logs to build a bulletproof dossier. Pair it with interactive 3D previews so decision-makers see both proof and visual impact.

5. Package data into marketing gold

Turn technical numbers into digestible visuals: infographics, short reels of the cullet journey, or QR-coded certificates embedded in finished pieces. Transparent material stories routinely boost average order value—similar to how eco-certified metal suppliers upsell premium brackets.

Cost and carbon calculus

Expect recycled cullet to cost 5-10 % more per tonne than virgin glass in some regions because of sorting labour. Yet furnace energy savings often neutralise the difference by the third production run. A quick payback chart shared with procurement teams makes approvals frictionless.

Common pitfalls and pro fixes

- Colour contamination: Run small test melts; adjust decolourisers instead of scrapping whole batches.

- Variable granulometry: Request sieve analyses; fine-tune batch recipes to control viscosity.

- Delayed shipments: Reserve buffer stock or maintain a supplier “B” like GreenShard to cover gaps.

- Client scepticism: Publish side-by-side LCA comparisons and link them to your limited-edition run strategy.

Pitch-ready checklist

- One-page spec sheet with COE, colour index, and cullet percentage.

- Copies of supplier eco-labels and batch analyses.

- Lifecycle impact infographic (energy saved, CO₂ avoided, waste diverted).

- Sample tiles or renders validating colour and clarity.

- End-of-life plan—suggest reuse or take-back schemes to mirror sculpture material loops.

FAQ

- How much recycled content can I safely add without compromising strength?

- Most soda-lime compositions accept 30–80 % cullet. Industrial lighting or architectural panels often stabilise at 60 % to balance viscosity and durability.

- Can I certify products if suppliers lack third-party audits?

- You'll need an independent test lab to verify purity and contamination levels before pursuing Cradle to Cradle or EPD labels.

- Does coloured glass always require colour-separated cullet?

- No. Amber and green cullet can tint clear compositions creatively, but run pilot melts first to predict hue shifts.

- What's the fastest way to prove traceability in a client pitch?

- Embed QR codes linking to a cloud folder containing supplier certificates, kiln logs, and photo evidence of each batch.

Quick quiz: Are you a recycled-glass sourcing pro?

Action steps

Audit your current batch recipes today. Identify at least one local cullet supplier, request purity certificates, and run a 10 kg pilot melt this month. You'll gather live data, trim energy bills, and secure talking points that eco-clients crave. Ready to claim the green edge? Let's make your next collection sparkle sustainably.