Eco-friendly drafting workflows: papers, inks and power budgets that win clients

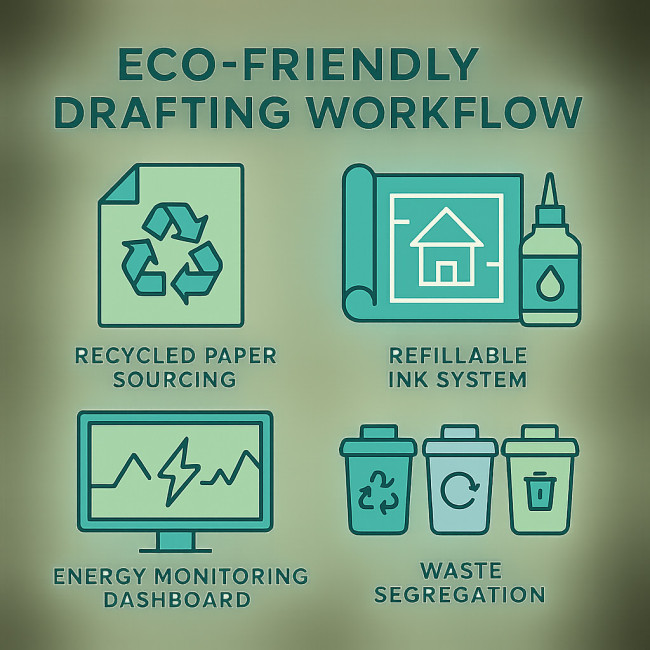

Greener drafting is no longer a nice-to-have. Clients now audit suppliers on carbon footprints, resource use and waste. This guide shows you how to build an eco-friendly drafting workflow—covering paper choices, ink systems and power budgets—that saves money, protects the planet and becomes a competitive sales argument.

Why an eco-friendly drafting workflow boosts your win-rate

Procurement teams add sustainability checkpoints to every brief. When your studio proves low-impact production, you instantly stand out against rivals who still rely on virgin papers, solvent inks and energy-hungry hardware. A documented eco-friendly drafting workflow reduces bid friction, unlocks larger frameworks and improves your brand reputation on platforms such as the Artfolio directory for image designers.

Three hard metrics clients ask for

- Grams of CO₂ per printed sheet

- Percentage of recycled fibre in media

- Annual kilowatt-hours consumed by drafting equipment

Selecting sustainable papers that still look premium

Paper is often your biggest material impact. The goal is to cut virgin fibre, minimise bleaching chemicals and keep archival quality high. The four options below fit most architectural and product-design use cases.

| Paper type | Recycled content | ISO brightness | FSC/PEFC certified | Typical price (€/A1) |

|---|---|---|---|---|

| Sugar-cane fibre bond | 100 % | 90 | Yes | 1.60 |

| Post-consumer cotton rag | 75 % | 92 | Yes | 2.10 |

| Bamboo vellum | 60 % | 89 | Yes | 1.90 |

| Conventional wood-pulp bond | 0 % | 96 | Optional | 1.20 |

Decision checklist

- Match paper weight to your largest format. Thicker bamboo vellum resists curl on plotters up to A0.

- Use chlorine-free bleaching to avoid downstream water toxicity.

- Add recycled-content stats to every project specification—procurement loves traceable figures.

You can deepen your material credibility by studying the broader sourcing tactics in this sustainable material roadmap.

Switch to non-toxic, refillable ink systems

Traditional solvent inks emit VOCs and require single-use cartridges. Modern water-based pigment sets deliver the same line sharpness, last longer under sunlight and slot into closed-loop refill programs.

Four fast wins

- Choose OEKO-TEX certified inks—zero heavy metals, zero formaldehyde.

- Adopt bulk tanks. They cut cartridge waste by 90 % and reduce cost per millilitre by half.

- Calibrate colour once per month; greener inks sometimes shift hues over time.

- Ship empties back to the supplier under free collection schemes.

Client-facing proof points

Provide Safety Data Sheets in your pitch deck. List VOC levels (mg/m³) and cartridge diversion rates. Clients evaluating eco-certified sourcing claims love comparable numbers.

Manage power budgets like a finance report

Energy use hides in idle workstations, over-spec GPUs and legacy plotters staying warm all week. A quick audit reveals surprising savings.

1. Downsize hardware where possible

Switching from a 600-W tower to a 90-W mini-PC for 2D drafting saves roughly 993 kWh per employee yearly. For 3D tasks, choose GPUs that support dynamic power scaling.

2. Schedule equipment sleep modes

- Plotters: Auto-sleep after 15 minutes. Wake latency is under 30 s on most models.

- Monitors: 10-minute blackout saves up to 60 W per seat.

- NAS drives: Spin-down overnight; cloud sync covers remote access.

3. Adopt renewable tariffs and track usage

If you sub-lease studio space, install smart plugs on large devices. Their dashboards create screenshots you can embed inside proposals to visualise live savings.

Building a transparent workflow document

Process visibility sells. Draft a one-page PDF that maps every sustainability step—paper sourcing, ink refills, power data and waste disposal. Link it in every bid email. You can repurpose the layer-naming logic explained in this remote onboarding guide for draftsmen to keep the document tidy.

Essential sections

- Media specs – recycled content certificates and sample IDs.

- Consumables cycle – supplier take-back schemes, cartridge counts.

- Energy dashboard – 12-month kWh graph with renewable percentage.

- Continuous improvement – next-quarter targets and responsible owner.

Price positioning: turn savings into margin

Eco-friendly drafting workflows are not always pricier. Lower energy bills and cheaper bulk inks often offset the slight premium on recycled papers. Pass a portion of these savings to clients as an “Efficiency Rebate”. The gesture validates your green claims and can secure longer retainer contracts—see how to structure them in this retainer agreement breakdown.

Case study: winning a retail build-out with 18 % lower emissions

An interior-architect practice in Lyon replaced wood-pulp bond with sugar-cane paper, adopted refillable pigment tanks and moved their CAD laptops to energy-efficient chipsets. Over six months, they:

- Cut paper-related CO₂ by 52 % (tracked via supplier LCA data).

- Saved €1,240 on ink spend despite a 12 % volume increase.

- Reduced workstation electricity by 1,800 kWh.

The sustainability appendix convinced the client to award a two-year framework agreement without a price renegotiation round.

Common pitfalls and how to avoid them

- Paper jams on bamboo vellum – update plotter feed tension and keep humidity below 55 %.

- Ink adhesion on coated media – run a nozzle alignment every 250 m² printed.

- Greenwashing accusations – always provide third-party certificates, not supplier brochures alone.

FAQ

- Does recycled paper compromise archival stability?

- No. Modern post-consumer fibres mixed with cotton rag achieve ISO 9706 permanence. Store prints below 25 °C and 60 % humidity.

- How do I calculate my drafting carbon footprint?

- Multiply paper weight by emission factor (kg CO₂/kg), add kWh × grid factor and divide by project deliverables. Free calculators exist on many paper suppliers' sites.

- Will water-based inks fade faster under sunlight?

- Not if pigment-based. Dye inks do fade. Choose pigment sets rated >200 yrs on ISO Blue Wool scale and use UV-stable laminates for outdoor sheets.

- Can I retrofit bulk tanks to an older plotter?

- Yes for most Epson and HP models made after 2018. Check warranty clauses; some vendors require certified installers.

- What if a client needs solvent-compatible media?

- Propose hybrid workflow: print solvent layers externally, keep all drafting proofs in water-based systems. Document the split to maintain transparency.

Ready to draft greener and win more briefs?

Embed these eco-friendly drafting workflow steps into your next proposal and watch client objections melt away. Need a quick checklist? Download the free template in the sidebar and start auditing your studio today.

Call to action: Want personalised advice? Book a 30-minute eco-workflow audit and uncover savings within a week—slots open this month.