Eco-minded sculpture materials: sourcing low-carbon clay, metal and resin

Searching for sculpture supplies that match your creative vision and your carbon-reduction goals? This guide compares the climate impact of clays, metals and resins, shows you how to vet suppliers, and shares smart swaps that keep both budgets and emissions in check.

Why carbon counts when you model in three dimensions

Every kiln firing, metal melt and resin cure releases greenhouse gases. The aggregate footprint of an exhibition's pieces can equal months of household emissions. By switching to lower-impact feedstocks and energy-efficient processes, sculptors now cut up to 60 % of embodied CO₂ without compromising durability or aesthetics.

Fast carbon snapshot of key sculpture materials

| Material | Typical CO₂ e (kg per kg) | Low-carbon alternative | Emission saving |

|---|---|---|---|

| Virgin stoneware clay | 0.40 | Locally sourced earthenware + solar kiln | -50 % |

| Bronze (virgin) | 4.00 | 90 % recycled bronze | -45 % |

| Aluminium (virgin) | 11.00 | Closed-loop recycled aluminium | -95 % |

| Epoxy resin (petroleum) | 6.10 | Bio-based epoxy (50 % plant content) | -65 % |

| Polyester resin | 5.60 | Recycled PET-derived resin | -40 % |

Clay: dig local, fire smart

1. Source within a 200 km radius

Transport can add 0.05 kg CO₂ per kg of clay for every 200 km travelled. Map regional pits via your craft-designer network and ask for mineral composition certificates to avoid contaminants.

2. Choose earthenware over high-fire bodies whenever possible

Earthenware matures at 980 °C vs. 1250 °C for stoneware. That saves around 30 % of the kiln energy per firing cycle. For outdoor work, pair lower-fire clay with high-performance sealants rather than defaulting to high-fire bodies.

3. Electrify and optimise your kiln

- Install programmable controllers to shave 10 % off energy use by fine-tuning ramps and soaks.

- Subscribe to a renewable electricity tariff. A 100 % green supply turns your kiln into a near-zero-carbon heat source.

Metals: recycled content is king

Metallurgical processes dominate the footprint of bronze, steel and aluminium. Switching from virgin ingots to recycled feedstock is the single biggest lever you have.

1. Verify recycled percentages

Ask foundries for Environmental Product Declarations (EPDs) that specify post-consumer and pre-consumer scrap ratios. A mix above 80 % recycled content typically halves emissions compared with virgin cast stock and can be highlighted on project proposals—ideal for eco-minded clients using eco-certified metal benchmarks.

2. Opt for induction melting

Induction furnaces cut energy demand by 40 % relative to coke-fired crucibles and eliminate direct fossil-fuel emissions on site.

3. Design for dematerialisation

- Hollow out cores where structural strength allows.

- Swap massive plinths for tension-rod supports or recycled-timber bases.

- Create modular pieces that can share armatures between exhibitions.

Resins: move from fossil to bio-based chemistries

Traditional epoxy and polyester resins carry one of the highest carbon intensities in the studio. Plant-based epoxies and recycled-plastic polyesters are rapidly reaching parity on cure time and clarity.

1. Decode percentage claims

“Bio-based” may mean anything from 20 % to 100 % renewable content. Push suppliers to disclose ASTM D6866 test results so you can document real impact for grant applications and for tenders that demand sustainable sourcing plans.

2. Plan low-waste mixes

Cure only what you need. Leftover mixed resin is landfill-bound and emissions-intensive. Spreadsheet batch sizes in grams per mould to keep wastage below 5 %.

3. Improve indoor air and cure efficiency

- Use vacuum-degassing to shorten cure cycles and reduce VOCs.

- Maintain workshop temperature at 22 °C; every additional 5 °C halves cure time and lowers heater runtime.

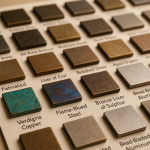

Carbon savings visualised

Source : European Circular Economy Platform

Supplier due-diligence checklist

- Traceability : request batch certificates or lot numbers for raw materials.

- Energy mix : ask if manufacturing sites operate on renewable power.

- Transport mode : prioritise rail or short-sea shipping over air freight.

- Waste policy : confirm that offcuts and scrap re-enter production loops.

- Social safeguards : verify fair-wage statements and worker safety audits.

Quiz: Test your eco-material instincts

FAQ

- Can I claim carbon credits for using recycled metals?

- In most regions, only large industrial recyclers can generate tradeable credits, but you can include verified savings in sustainability reports to enhance project value.

- Are plant-based resins food-safe?

- Not automatically. Always request migration test data (EU 10/2011 or FDA 21 CFR) to confirm suitability for functional ware.

- How do I dispose of unused mixed bio-resin?

- Once cured, treat as inert solid waste. Some municipal schemes accept it for energy-from-waste; liquid leftovers remain hazardous.

- Does low-fire clay compromise outdoor durability?

- When sealed with breathable siloxane coatings, frost resistance rivals that of mid-fire bodies, provided wall thickness stays below 20 mm.

Next steps: turn knowledge into low-carbon masterpieces

Shortlist suppliers, run small-scale tests, and update your client briefs to highlight carbon savings. For deeper dives into circular metals, explore our guide on soil-safe material selection. Looking to certify your studio workflow? Compare process metrics with peers using recycled-material sourcing playbooks.

Ready to sculpt sustainably? Audit your current material mix this week and set a measurable reduction target for your next commission.