Fragile no more: packaging specs for safe international glass shipments

Exporting glass art or tableware should fuel growth, not keep you awake at night. Follow the technical guidelines below to slash breakage, sail through customs and delight overseas clients with pristine pieces.

Why glass breaks in transit

Three forces threaten every crate: shock during drops, vibration over long hauls and pressure changes in cargo holds. Understanding these variables helps you choose materials that absorb energy rather than transfer it to your work.

Core packaging specs you must lock down

1. Cushioning material minimums

Industry testing shows borosilicate vessels survive 80 cm drops when surrounded by 7 cm of dense polyurethane or 10 cm of loose-fill. The ratio matters more than the brand.

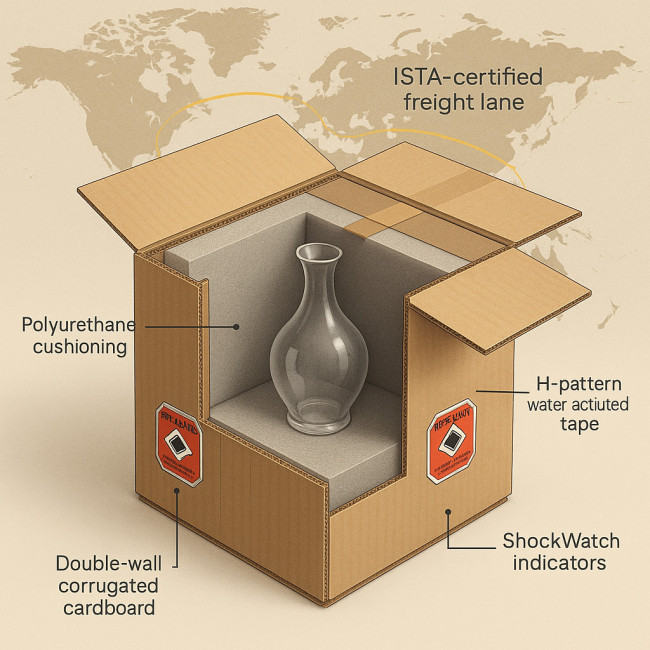

2. Box strength and size ratios

Select a double-wall corrugated box with an Edge Crush Test (ECT) rating ≥ 44 lbs. Internal volume should be 2,5 × the object's volume; smaller leaves no room for cushioning, bigger encourages movement.

3. Internal dividers and isolation

Use cell dividers of 200 gsm micro-flute cardboard for sets. Each item must stand at least 5 mm from any divider wall. For sculptures with protrusions, add custom die-cut EVA inserts as illustrated in the fragile-ceramics shipping guide.

4. Environmental controls

Desiccant packs (minimum 60 g per 0,04 m3) keep relative humidity under 45 %. Temperature indicators alert clients to potential annealing stress if cargo sat on tarmacs.

5. Compliance marks and documentation

Print ISO 780 “Fragile” and “This Side Up” symbols in black ≥ 10 cm high. Affix the commercial invoice outside in a waterproof pouch to minimise customs handling.

| Pack element | Specification | Industry benchmark | Practical tip |

|---|---|---|---|

| Cushion gap | 7-10 cm all sides | ISTA 3A | Use rulers—eyeballing fails under pressure. |

| Box board | Double wall, 44 ECT | FedEx Fragile Pack | Write ECT rating on purchase orders. |

| Inner wrap | 150 µm polyethylene foam | UN337 Packaging | Foam beats bubble wrap for sharp edges. |

| Void fill density | ≥ 1,5 lb/ft³ | UPS Test Lab | Heavier fill keeps items immobilised. |

| Closure | Water-activated tape, 7,2 cm | ASTM D1974 | Two bands in H-pattern resist humidity. |

Step-by-step packing workflow

- Inspect and clean. Remove dust; small particles create micro-scratches during vibration.

- Apply primary wrap. Two clockwise layers of polyethylene foam, joints secured with low-tack tape.

- Create suspension. Pour 5 cm of loose-fill into box, seat the wrapped object, add more fill until top clearance equals bottom.

- Add dividers. Slide pre-cut micro-flute sheets for multi-item shipments.

- Insert indicators. Place ShockWatch and humidity cards on box interior walls for quick visual checks.

- Seal and label. Use water-activated tape in an H pattern; apply orientation arrows on all vertical faces.

- Document. Photograph each step—evidence for insurers and curious collectors in the 3D preview workflow.

Carrier selection and insurance hacks

Choose carriers that provide ISTA-certified freight lanes. For glass under USD 5 000 value, the carrier's declared value option can suffice; above that, third-party “all risk” art insurance is cheaper per dollar covered. Compare premiums after reading our glassware gifting blueprint, which details how perceived fragility affects margin.

Customs paperwork essentials

- HS code 7013.99 for decorative glassware.

- Country-of-origin certificate. Speeds duty assessment, especially in the EU.

- Fumigation statement. Only needed if using wooden crates, but many officers ask—have it ready.

- Insurance certificate. Attach copies inside and outside to prevent hold-ups.

Common mistakes to avoid

Under-filling voids. Even 1 cm of empty space lets items rattle. Mismatched materials. Bubble wrap and starch peanuts compress at different rates, causing shifts. Ignoring ambient pressure. Air pockets expand in cargo holds; bleed any inflatable bags to 70 % before sealing.

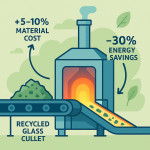

Eco-friendly upgrades

Cushioning made from recycled paper honeycomb cuts plastic use by 60 %. Learn sourcing tricks in the recycled glass sourcing playbook. Pair this with natural rubber tape to meet corporate sustainability policies without sacrificing strength.

Quality control checklist before pickup

- Shake test: no audible movement.

- Corner crush: press each box corner—any softness means under-spec board.

- Label legibility: symbols visible from 5 m.

- Weigh and record: variance > 1 % from spec weight flags packing inconsistency.

Build client confidence

Share your documented process on the craft-designer directory. Pictures of compliant crates reassure buyers and often justify premium fees.

Quick self-assessment quiz

FAQ

- Do I need wooden crates for all international glass shipments?

- No. Double-wall corrugated boxes with the specs above pass most airline and courier tests up to 32 kg. Use wood only for oversize or museum pieces.

- What is the safest courier for glass?

- Rather than one “safest” brand, look for carriers offering ISTA-certified lanes and real-time shock monitoring.

- How do I handle returns without repacking on site?

- Include a pre-folded return kit inside the original parcel: spare tape, indicator labels and a QR code to a short repack video.

- Can I insure recycled-glass art at the same rate as crystal?

- Yes. Insurers base premiums on declared value and fragility, not material cost. Provide process photos to prove structural integrity.

Take action

Adopt the specifications today, update your supply sheet and share your upgraded crates on client calls. Your next overseas collector deserves to unbox perfection.