Material sourcing tricks that slash lead-times for landmark mosaic walls

Designers and contractors regularly lose weeks waiting for tiles, tesserae or specialty binders to arrive. This guide reveals the most effective material sourcing tricks that slash lead-times for landmark mosaic walls without compromising quality, budget or heritage specs.

Why lead-time balloons on large-scale mosaic walls

Three hidden bottlenecks

- Fragmented supplier chains —glass, stone and metallic accents often come from three different regions, multiplying customs checks.

- Batch-matching constraints —architects request colour lots fired within 48 hours of each other; waiting for a full kiln load stalls production.

- Documentation drag —heritage boards and insurers demand quarry certificates, ASTM test reports and maintenance manuals before work begins.

Each hurdle adds days—or months—to a schedule. The following tricks eliminate or shorten those steps so your next landmark mosaic wall stays on track.

Seven material sourcing tricks that slash lead-times

1. Lock flexible colour specs before concept sign-off

Ask the designer to approve ranges—e.g., “emerald 320–340 nm wavelength” rather than one Pantone chip. Kilns can then fire available frits immediately, saving an average five-day wait for custom pigment mixes.

2. Use quarry-direct stone portals

Several Mediterranean quarries now run live inventory portals with 24-hour payment confirmation. Ordering travertine direct shaves 10–14 days compared with legacy brokers. Combine this with the sustainable sourcing roadmap to keep ESG officers satisfied.

3. Pre-buy recycled glass cullet in bulk

Glass tesserae require cullet with <0.02 % lead. Secure a six-month blanket order of certified cullet; you'll feed multiple projects without repeat lab tests. See the in-depth recycled glass sourcing playbook for audit pointers.

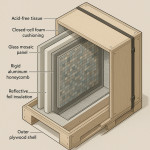

4. Swap exotic metals for locally coated aluminium

Mosaicists often specify bronze or brass inlays that travel 8 000 km. A marine-grade aluminium core with PVD bronze coating meets EN ISO 9227 salt-spray tests and ships regionally in three days—saving up to two weeks.

5. Align firing slots with kiln partners

Independent studios rarely run kilns at full capacity. Partner with two studios on opposite production cycles. Should one kiln fail, the second absorbs volume the same week, preserving your critical path.

6. Combine documentation into one digital spec sheet

Merge fire-rating, slip-resistance and cleaning instructions into a single PDF. Approvers sign once, not three times. Borrow templates from these award-winning mosaic spec sheets.

7. Book a freight consolidator specialising in oversize art

Crating fragile panels with other architectural finishes halves customs inspections. Compare rates in the oversized mosaic freight guide to avoid hidden pallet fees.

Cost-speed matrix for the top sourcing tricks

| Trick | Average lead-time saved | Extra cost (+/-) |

|---|---|---|

| Flexible colour specs | 5 days | 0 € |

| Quarry-direct portal | 12 days | -5 % (broker margin removed) |

| Bulk recycled glass cullet | 8 days | +2 % (storage) |

| Local PVD aluminium inlays | 14 days | -3 % |

| Dual-kiln partnerships | 7 days (downtime offset) | +1 % (retainer) |

| Unified spec sheet | 4 days | 0 € |

| Specialised freight consolidator | 6 days | +4 % (premium service) |

Compliance and sustainability shortcuts

Large public murals must satisfy LEED, BREEAM or HQE credits. The fastest path is to source pre-certified tiles. Many suppliers already list EPDs (Environmental Product Declarations) online. Pair those with quarry emission reports and you'll breeze through green-building audits. By collecting cradle-to-gate CO2 and water-use metrics during the tender phase, you also position the artwork for circular-economy labels demanded by city councils from Oslo to Barcelona. These datasets later feed smoothly into digital twin models that facility managers rely on for lifecycle tracking.

Need extra credibility? Feature your sustainable sourcing achievements on your profile at the craft design specialist directory visited by heritage architects worldwide.

30-day express workflow: from quarry to job site

- Day 0–2 : lock flexible colour palette, confirm tile counts with BIM take-off.

- Day 3 : place quarry-direct and cullet orders, book kiln slots.

- Day 4–10 : receive stone, process recycled glass batch one; begin water-jet cuts.

- Day 11–16 : fire glass tesserae, apply PVD coatings to aluminium accents.

- Day 17–19 : assemble mock-up panel, gather test data for unified spec sheet.

- Day 20–22 : digital sign-off from architect and insurer.

- Day 23–26 : crate panels, load with consolidator.

- Day 27–30 : clear customs, deliver onsite, begin installation.

Quality control tips while accelerating

- Run a spectral scan on every tenth glass batch; variance <2 % keeps colour harmony.

- Use laser-cut alignment grids to pre-stage panels and reduce onsite trimming.

- Apply QR-coded labels; installers scan for placement maps, eliminating paper plans.

FAQ

- Can fast-tracked materials still pass heritage board reviews?

- Yes. Boards focus on provenance and durability, not delivery times. Provide quarry certificates and accelerated-aging test results in the unified spec sheet.

- Is aluminium really as robust as bronze for outdoor mosaics?

- Marine-grade alloys with PVD coatings meet the same corrosion cycles. They weigh 60 % less, cutting structural loads and freight costs.

- What if my recycled glass cullet supply runs dry mid-project?

- Negotiate a blanket purchase order with a “call-off” clause and maintain 15 % safety stock. Dual sourcing from two regions buffers geopolitical risk.

- How do I keep colour consistency with flexible specs?

- Define tolerance windows in nanometers or LAB values, then test small-batch samples before full production. The variance is invisible at mural viewing distance.

- Does consolidating freight endanger delicate panels?

- No—specialised art consolidators build custom crates with vibration sensors. Insurance premiums are equal or lower due to lower claim rates.

Ready to shorten your next schedule?

Implement at least three of the material sourcing tricks above and benchmark your lead-times. Clients notice on-time delivery—and so do tender committees. Need help integrating the full workflow? Contact our studio or explore complementary guides like building mosaic artist partnerships for public art bids to secure experienced collaborators.