Spec sheets that win architects: detailing mosaic durability and upkeep

Architects compare dozens of surface finishes every week. A crystal-clear spec sheet can pivot their choice toward your mosaic studio. This guide shows exactly which durability and maintenance data convince decision-makers fast—and how to present them.

Why architects scrutinise mosaic spec sheets

Architects are risk managers. They balance aesthetics, cost, and long-term performance for every square metre they specify. A mosaic installation combines grout lines, tile bodies, and mounting systems—all potential failure points if data are vague. Your spec sheet must reassure them that:

- the mosaic will survive local climate cycles;

- maintenance costs stay predictable over decades;

- the finish meets building codes and sustainability targets.

Achieve that, and you move ahead of suppliers who email generic brochures. For public tenders, a tight spec even helps architects defend their choice during value-engineering rounds.

Core durability metrics to include

Provide third-party test results where possible. Architects love numbers backed by recognised standards such as ASTM, EN ISO, or ANSI.

Water absorption rate

Masonry walls breathe; indoor pools splash; façades soak in driving rain. List the percentage of water your tile body absorbs after 24 hours (ASTM C373). For exterior cladding, aim below 0.5 %; interior features tolerate up to 3 %.

Freeze–thaw resistance

Show cycle counts, not marketing adjectives. For example: “No visible cracking after 300 cycles at –15 °C / +15 °C (ASTM C1026).” If you source winter-proof materials, detail them in a dedicated addendum or link to our smart material sourcing guide.

UV stability

Glass tesserae resist fading, but pigments in some recycled fillers can yellow. Include ΔE colour change after 2 000 h of Xenon arc exposure (ISO 105-B04). If you propose a UV-sheltered indoor mural, state it clearly: context matters.

Bond strength

Architects want assurance that mesh or paper face mounts won't fail. Quote shear bond strength of the full assembly (tile, adhesive, substrate). A value above 2 MPa under wet conditions is a confidence booster.

Slip resistance

For floors, show both wet and dry coefficients of friction (COF ≥ 0.42, ANSI A326.3). Include microtexture photographs with alt text like  to enrich the digital file for accessibility.

to enrich the digital file for accessibility.

Source : International Mosaic Art Association

Upkeep lifecycle: what to promise and prove

Mosaic maintenance costs come from grout resealing, joint inspections, and occasional replacement of chipped tesserae. Outline a 30-year maintenance schedule:

| Year | Recommended task | Estimated cost €/m² |

|---|---|---|

| 0 | Initial sealing with nano-silane coat | 5 |

| 5 | Visual inspection, spot re-grout | 2 |

| 10 | Complete reseal, colour refresh | 4 |

| 20 | Non-destructive bond testing | 3 |

| 30 | Joint overhaul (5 % tile swap) | 8 |

By quantifying upkeep, you reassure facility managers and reduce objections at the budgeting stage. Pair this with contract clauses outlined in our maintenance clause primer.

Formatting a spec sheet architects love

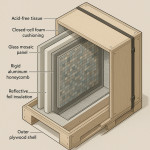

- One-page executive summary—include a hero image, key metrics, and certification logos.

- Clickable deep dive—link each metric to lab certificates stored on your verified designer profile for instant due diligence.

- Editable CAD annotation—supply .dxf or .rvt files with layer naming that matches the spec language.

- Reference projects—feature a comparable climate zone and present before/after maintenance photos.

- Contacts and lead time—state maximum production weeks and bundling options such as safe crating standards.

Common red flags and how to pre-empt them

Architects ditch suppliers once they see:

- “proprietary blend” with no chemical breakdown;

- missing grout compatibility tables;

- no guidance for complex surfaces like curved façades;

- unclear warranty language—always match local construction law.

Your fix: attach a technical addendum with allowable tolerances, recommended adhesives, and a warranty template that spells out workmanship and material coverage. For digital persuasion, offer 3D mock-ups architects can orbit in BIM viewers.

Quick knowledge check

FAQ

- How detailed should bond strength data be?

- Include shear and tensile values, temperature and humidity conditions, plus the test standard used. Granularity builds trust.

- Can I reference small private projects as case studies?

- Yes, if they match the proposed usage conditions. Highlight lessons learned and maintenance results.

- What if lab tests are still in progress?

- Provide provisional figures and the expected certificate date. Architects prefer transparency over silence.

- Which file format is best for colour swatches?

- Supply both sRGB JPG for quick viewing and ASE palettes for Adobe suite integration.

- Do architects care about recycled content percentage?

- Increasingly, yes. State post-consumer and post-industrial ratios and link to our recycled glass sourcing playbook.