Eco-smart display materials: choose planet-friendly props without budget blowouts

Looking to refresh your shopfront or pop-up without trashing the planet—or your profit margin? This guide breaks down eco-smart display materials, compares real cost brackets, shows how to lock reliable suppliers and gives you a step-by-step rollout plan that keeps CFOs and climate-conscious customers equally happy.

Why eco-smart display materials should top your prop list

Visual merchandising drives up to 65 % of unplanned in-store purchases, yet conventional PVC, foam board and virgin acrylics come with high embodied carbon and landfill lifespans longer than the product's trend cycle. Switching to eco-smart display materials lowers Scope 3 emissions, scores instant ESG points and boosts brand perception: 73 % of Gen Z shoppers say they'll pay more for sustainable store experiences.

Brands that already swapped to greener substrates report double-digit savings on end-of-season waste fees. To replicate their success, you must balance three metrics: material cost, durability window and end-of-life scenario.

Key impact metrics to track from day one

- Carbon footprint (kg CO₂e/m²): compare recycled vs. virgin content.

- Recyclability rate (%): ask for third-party audit certificates.

- Cost per visual exposure hour: divide material + labour by predicted display lifespan.

Five planet-friendly substrates that won't nuke your budget

| Material | Typical Cost €/m² | Durability (weeks) | End-of-life Route | Best-fit Use |

|---|---|---|---|---|

| Recycled Cardboard Honeycomb | 4-7 | 6-8 | Paper stream | Window props, lightweight shelves |

| Mycelium Foam Panels | 9-12 | 4-6 | Industrial compost | Organic-themed pop-ups, plinths |

| Re-board® (FSC Recycled Fiber) | 8-10 | 10-12 | Paper stream | 3-D letters, freestanding totems |

| R-PET Sheet (50 % ocean plastic) | 11-14 | 12-16 | Closed-loop take-back | Clear signage, product risers |

| Bamboo Plywood | 13-18 | 18-24 | Reuse or biomass | Premium back walls, shelving |

Notice how most options land below €15 per square metre—significantly cheaper than cast acrylic (€22-€30) yet with vastly lower carbon footprints.

Budget planning: four levers to keep costs down

- Modular design first. Panels cut to standardised grid sizes let you re-use frames, reducing next season's spend by up to 35 %.

- Supplier consolidation. Bundling print and cutting services trims logistics fees; learn more tactics in our sustainable material sourcing playbook.

- Lifecycle agreements. Ask vendors about take-back or recycling rebates—Re-board® offers €1.20 credit per kg returned.

- Data-driven prototypes. Trial micro-sets in one flagship store, track footfall via heat sensors, then scale. This mirrors the workflow outlined in our scenography roadmap.

Supplier vetting checklist

- Request ISO 14001 certification plus material safety data sheets.

- Verify recycled content claims through third-party audits such as Recycled Claim Standard.

- Inspect print inks: favour water-based, VOC-free formulations to align with in-store air-quality regs.

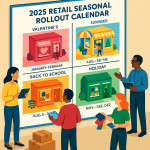

- Cross-check lead times with your seasonal display calendar to avoid emergency premium shipping.

Step-by-step rollout plan

- Audit current assets. Map every window and in-store display, noting sizes and refresh frequency.

- Match materials to exposure window. Short campaign? Opt for mycelium or cardboard. Long stint? Bamboo or R-PET.

- Create CAD templates. Keep cut files in a digital asset vault for fast re-orders.

- Pilot & measure. Use QR codes on props to log customer dwell time; if uplift ≥10 %, green-light wider roll-out.

- Scale with circular logistics. Partner with a regional recycler—tips in this metals sourcing guide.

Case snapshot: circular shopfront in 21 days

Indie fashion label MINTED swapped PVC mannequins for cardboard honeycomb torsos, printed with soy ink. Production cost dropped 28 %, install weight shrank 65 % (no pallet jack needed) and the brand redirected €3,400 from waste disposal to influencer-led launch content. The project team found their freelance spatial designer through the Artfolio spatial designers directory, accelerating concept-to-build sign-off to just nine days.

Common pitfalls and how to dodge them

- Warping in humid storefronts. Seal cardboard edges with plant-based varnish.

- Colour shift under LED spots. Request lightfastness rating ≥7 on Blue Wool Scale.

- Fire-code misses. Always ask for Euroclass B or UL94 V-0 certificates on bamboo sheets.

- Last-minute décor swaps. Store spare flat-packed panels in back-of-house; they occupy 70 % less space than molded plastics.

Quick self-assessment quiz

FAQ

- Are eco-smart display materials more fragile than traditional plastics?

- Not necessarily. Re-board® and bamboo plywood match or exceed the crush and flex strength of PVC foam. Always factor correct load-bearing specs.

- How do I dispose of mycelium props after a campaign?

- Send them to an industrial composting facility where they decompose within 45 days. Home composting is possible but slower.

- Can I print full-colour graphics on recycled cardboard?

- Yes. Digital flatbed presses using water-based inks deliver photo-quality results while staying VOC-free.

- What if my city lacks a recycling partner?

- Negotiate a take-back clause with the material supplier; many consolidate batches regionally before processing.

- Will switching materials affect installation time?

- Installers usually report 20-30 % faster builds because lightweight panels need fewer fixings and no specialist lifting gear.

Next steps

Blend the insights above with data from our display ROI tracker (coming soon) and you'll be equipped to roll out climate-positive, cost-neutral windows that reel in conscious consumers and slash waste bills.

Ready to upgrade? Download our printable checklist and brief your visual merch team today.