Global install logistics: pack, ship and mount fragile displays with fewer returns

Shipping a statement window display from Paris to Shanghai, mounting it overnight and seeing zero breakage – that is the promise of flawless global install logistics. In this guide, you will learn how to engineer protective packs, select climate-smart routes, and brief installers so your fragile displays arrive intact and shine on site, no matter the continent.

Why fragile displays suffer high return rates

Retail props, museum maquettes and experiential pop-ups combine glass, mirror, LEDs and delicate finishes. Once these hybrid builds leave the workshop, they face vibration, temperature swings and handling by teams who may never have seen the piece assembled. The result: chipped edges, hairline cracks, scratched acrylic and customer returns that cripple margins.

- 37 % of damages occur during the first kilometre – usually while loading.

- 52 % of breakages trace back to inadequate inner cushioning, not external impacts.

- 11 % of losses come from mounting errors, often because fixings were misplaced in transit.

The global install logistics roadmap

1. Pre-project assessment

Start with a bill of materials and centre-of-gravity map for every component. Use those measurements to calculate g-forces each part can survive. A quick finite element simulation costs less than a reshoot of a cracked display.

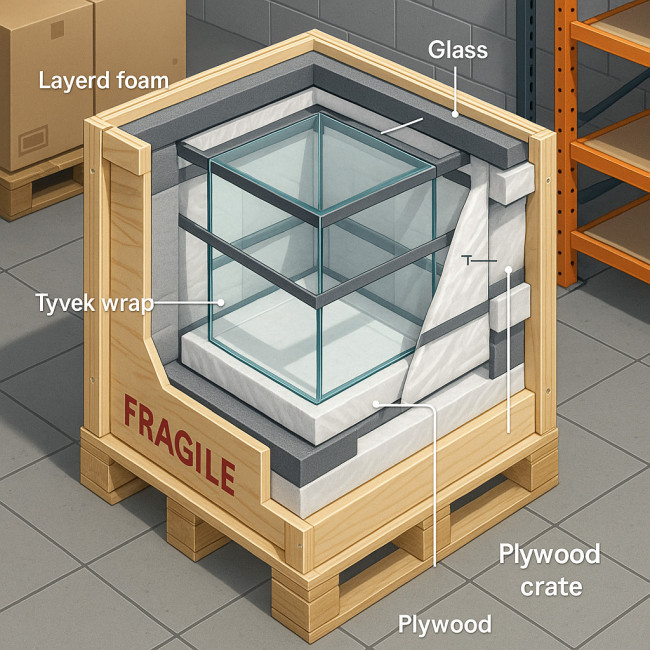

2. Engineering the right pack

Match packing architecture to the item's weakest point. A backlit acrylic sheet needs face-pressure protection, while a frosted glass sphere needs omnidirectional cushioning. Combine these layers:

| Layer | Material | Function | When to use |

|---|---|---|---|

| Primary wrap | Tyvek® sleeve | Dust & scratch barrier | Glossy or painted surfaces |

| Cushion | 40 kg/m³ closed-cell foam | Absorb shock | Items < 25 kg |

| Suspension | Elastomer bands | Float object | Fragile cores like neon |

| Shell | ISPM-15 plywood crate | Stacking & impact | Air & sea freight |

Need deeper foam specs? Our article on packing standards for fragile objects dives into density formulas that cut breakage by 28 %.

3. Climate-smart route planning

Heat and humidity weaken adhesives, so route acrylic-heavy builds through temperate hubs. If you must fly via Doha in August, add silica gel and warn the forwarder to avoid hot tarmac holds longer than 45 minutes.

Tip: add “controlled-temperature service mandatory” in the air waybill's handling remarks. Airlines prioritise space in climatised compartments when wording is explicit.

4. Selecting a carrier and insurance wrapper

Choose carriers with ISO 9001 and on-airport X-ray that fits oversize crates, reducing unboxing for inspection. Pair the shipment with an all-risk, nail-to-nail policy so coverage starts at the studio door and ends after mounting.

For projects exceeding €50 k, consider the bonded-cargo route explained in our crating and freight guide. It keeps valuation transparent for customs and insurers alike.

5. Real-time tracking & contingency triggers

- Attach two NFC loggers: one on the crate wall, one on the inner suspension plate.

- Set SMS alerts at 17 °C and 35 °C thresholds, plus 25 g shock.

- If any threshold trips, auto-notify the installer to extend acclimatisation time on site.

6. On-site mounting protocol

Ship a QR-coded digital twin alongside each display – a 3D PDF with exploded views and torque values. The local crew scans, receives step-by-step visuals and reduces missing-hardware mistakes by half.

Need guidance on remote hand-offs? See how prototype object teams manage overseas installs in this sample-shipping workflow.

Insurance and documentation essentials

Logistics is risk management as much as movement. Provide your broker with:

- Packing declaration signed by the fabricator.

- High-resolution photos of each stage of crating.

- Value breakdown (materials, R&D, creative fee) – vital for claim disbursement.

- Mounting certificate from the installer post-assembly.

From project launch, store those files in a shared vault. Recruiters browsing the spatial design directory increasingly shortlist studios that show this paperwork upfront.

On-site techniques that minimise damage

No matter how perfect the crate, mishandling during mounting can undo months of planning. Adopt these habits:

- Float before fasten. Always hover the display 5 cm from the wall to confirm cleat alignment.

- Torque maps. Pre-print a map marking exact Newton-metres for each screw.

- Protective peel. Leave film on glossy faces until all lighting adjustments are complete.

- 48-hour acclimation. For laminates or composites, let them reach ambient humidity before energising LEDs.

Case study: 6 m LED glass ribbon, Milan → Dubai

The client demanded installation during mall off-hours. By combining a suspension crate, dual data loggers and an on-site torque-mapped cleat, the team achieved zero breakage and met a five-hour mounting window. Return rate: 0 %. Warranty claims: 0 €. That performance secured a follow-up contract for three additional stores.

Checklist: from warehouse to wall

- Confirm final drawings and centre of gravity.

- Choose pack architecture (foam grade, suspension, crate spec).

- Book carrier with climate control and oversize X-ray.

- Issue all-risk insurance including mounting period.

- Integrate NFC and temp/shock loggers.

- Prepare 3D digital twin with torque data.

- Schedule acclimatisation window into build calendar.

- Capture photos at pack-up, load-out, uncrate and mount.

- File mounting certificate and logger report.

- Debrief and update pack template for next rollout.

Try your hand: quick logistics quiz

FAQ

- Do I need different crates for air and sea freight?

- Yes. Sea shipments face prolonged humidity, so add vapor barrier bags and IP-67 desiccant canisters.

- How early should I book climate-controlled cargo space?

- Minimum ten working days in advance; premium lanes sell out fast during fashion and design weeks.

- Can I reuse suspension crates?

- You can if shock indicators remain green and foam memory has not compressed more than 10 %.

- What documents speed up customs clearance for art displays?

- A pro-forma invoice, ATA carnet and high-resolution images referenced in the object list.

Next step: optimise your workflow

Ready to slash damage rates on your next rollout? Book a discovery call and we'll draft a bespoke global install logistics plan that blends temperature-controlled transit, suspension packing and on-site torque mapping. Your displays deserve to arrive flawless – and your brand deserves the savings.