Supplier sourcing made easy: vet prop fabricators that meet brand quality marks

Need props that look flawless on launch day and survive a month-long retail installation? Follow this actionable roadmap to shortlist, vet and onboard prop fabricators that consistently meet brand quality marks—without draining your timeline or budget.

Why a rigorous vetting process pays off

Switching vendors every season costs more than it seems. Re-briefing, extra sampling rounds and emergency reprints often double hidden costs. A structured vetting workflow locks in:

- Brand consistency—colour, finish and durability stay on spec across campaigns.

- Reduced rework—fewer surprise defects or compliance failures.

- Faster rollouts—a trusted supplier can fast-track complex builds.

Brands that nurture long-term fabricator relationships report up to 18 % lower total install costs than those hopping between “cheapest” quotes.

Core quality marks your prop fabricator must prove

Material certifications

Ask for third-party certificates that match your brand promises—FSC for wood, OEKO-TEX 100 for textiles, or ISO 14001 for eco-friendly facilities. Suppliers specialising in eco-smart display materials often publish these documents proactively.

Workmanship tolerances

- Colour delta E ≤ 2 on Pantone-critical projects.

- Edge radius < 0.5 mm on CNC-cut acrylic to avoid visible seams.

- Load tests that simulate public interaction for interactive props.

Compliance & safety

Fire-retardant ratings (M1, NFPA 701) and REACH documentation are non-negotiable, especially for window displays that must respect local fire codes. Review our fire and safety checklist before signing any PO.

Five-step sourcing workflow that de-risks every order

- Draft a bullet-proof spec sheet. Include exploded views, finish swatches, tolerances and an install environment description.

- Shortlist suppliers through trusted hubs. Directories such as the Spatial Designers directory filter vendors by material expertise and capacity, saving hours of cold outreach.

- Request paid samples—never freebies. Charging a small test-run fee pushes the supplier to treat samples as mini-production, revealing true quality.

- Audit facilities remotely. Video walk-throughs, ISO certificates and maintenance logs expose bottlenecks early.

- Lock in a performance-based contract. Tie 10–15 % of the invoice to on-site QC sign-off to keep standards high.

Red-flag detector: evidence to request at each checkpoint

| Checkpoint | Evidence to request | Red flag if missing |

|---|---|---|

| Material sourcing | Certificate numbers, batch IDs | Generic “eco-friendly” claims |

| Colour accuracy | Spectrophotometer report | Only smartphone photos |

| Fire safety | Recent lab test (≤ 12 months) | Out-of-date or supplier-created report |

| Load bearing | Static load test video | No load data for interactive props |

| Packing & shipping | ISTA 3A drop test | “Fragile” stickers as main strategy |

Lead-time realities: set expectations early

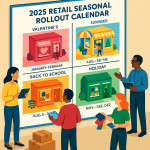

Many planners still assume offshore production is always slower. The chart below shows why supplier type, not geography, predicts turnaround.

Source : European Visual Merchandising Benchmark 2024

Packaging & logistics: don't let quality crumble in transit

Even perfectly finished props arrive ruined if shipped poorly. Include ISTA-compliant packing in your RFQ and refer suppliers to our guide on shipping fragile displays for best practices. Use double-walled cartons, custom-cut foam inserts and humidity indicators so receiving teams can verify handling conditions the moment freight is signed off. Adding tilt sensors and shock logs costs pennies yet offers invaluable proof if a carrier dispute arises. These small, proactive safeguards dramatically reduce breakage incidents, protect your installation timeline, and preserve the showroom-fresh finish your brand promises—no emergency repaints, no disgruntled store managers, just flawless props ready for window spotlight.

Costing smarter: total landed price over unit price

Factor in freight class, import duties and rework risk. A premium local vendor charging 12 % more per unit can still save 8–10 % overall once you add overseas freight, duty and contingency buffers.

Contract clauses that protect brand quality

- Master Service Agreement listing quality marks as enforceable KPIs.

- QC checkpoints—pre-production sample, mid-run inspection, on-site sign-off.

- Penalties tied to % of units out of spec, not vague “best effort” wording.

- IP & confidentiality—prevent replica props flooding discount markets.

FAQ

- What is the quickest way to pre-qualify new fabricators?

- Request their latest audit certificate (ISO 9001 or equivalent) and a timestamped shop-floor video. Vendors who reply within 24 hours usually have organised documentation and workflow discipline.

- How many samples should I request before a large roll-out?

- Order at least three units: one for destructive testing, one for executive sign-off and one to keep as a golden reference during mass production.

- What if the supplier is overseas but ticks all quality boxes?

- Budget extra lead time for freight and book a third-party QC agency in the country of origin. This costs 2–4 % of the invoice and cuts defect-related delays by up to 70 %.

- How do I secure my design IP?

- Include NDA clauses, watermark CAD files and release editable files only after the first successful production run.

- When should I sign a framework agreement instead of one-off POs?

- Once a supplier has delivered two consecutive defect-free batches, move to a 12-month framework. You gain better pricing tiers and guaranteed capacity during peak seasons.

Quick knowledge check

Next step: lock in a pilot run

Ready to move from theory to real-world savings? Issue a pilot RFQ to your shortlisted fabricators this week and use the evidence checklist above to score each response. Your future installations—and your brand reputation—will thank you.

Need deeper guidance? Book a free 30-minute sourcing audit with our team and get a contract template tailored to your next campaign.